Back in 2013 I was invited to show a bicycle at the Portland Art Museum. I was told there would be a collection of around 40 historic bicycles on display, and there would be space in the foyer for myself and other local builders to show off some of our work. At around this time, hand made bicycles were at the peak of their popularity, and I thought, Wow, this is likely a once-in-a-lifetime opportunity. I mean, how many people get to make something with their own hands and display it in a major museum?

I didn’t want to show a regular ol’ bicycle. The chance to get a bike in a museum seemed to warrant that I make something really spectacular. I mean, why not? It had to be unique, kind of Ahearne-style — practical, functional, a little bit weird, you would have to study it to be able to take it all in. It had to satisfy my general requirement that any bike I build be useful, not just a pretty display, which means it had to ride well, and do what it was intended to do — in this case, tour; carry bags and a rider, and it had to do this well. I wanted it to be able to break the bike down to fit in a travel case, so it had to have couplers. I chose 26” wheels — the international standard for bicycle tire size. Of course generator-powered lights, fenders, racks. A bonus u-lock holder. Double top tube for stability front-to-back, which opened a perfect space for a frame bag. Disc brakes. Triple front and 9 speed rear drive train (still, in my opinion, one of the best and most reliable for touring) with some swanky new/old stock derailleurs I’d found — Shimano XTR M900. My favorite drop bar shifter system made by Gevenalle. Comfortable, all-day-riding geometry. Basically, everything I would want if I were on an extended bike tour. All the way down to the removable titanium spork head badge. The whole bike is polished stainless steel because… Well jeez, just look at it. On the practical side this finish sheds mud, dirt, water.

But really, just look at it.

When I began this project I’d been building frames as my full time job for about ten years. This bike was the culmination of all my skills and best ideas at that point. It was an ambitious project, and took me way too long to make — literally months. It challenged all my technical abilities, not to mention my soul. The bike itself is quite possibly too complicated, but I won’t be the one to judge. I set out to make it my very best work, and this bike is what came out of it. And I can verify it does in fact ride well, although it has never been on an extended cycling tour. All in all the bike has fewer than twenty miles on it. Which kind of begs the question — What has this bicycle been doing for the past eight years?

After displaying the bike in the museum I took it back to my workshop and stored it in a back room until the following year, 2014, when I packed the bike into a travel case and took it over to the UK to display it at the Bespoked Hand Made Bicycle Show. That year the show was in London, at the Lee Valley Velopark. I rode the bike back and forth across the city a few times, between my rented room and the bike show — I used it as my commuter. These rides through London traffic were a bit nerve-wracking, mainly because I wasn’t used to the opposite-side orientation of the roads. And, you know, the bike didn’t quite feel like it belonged to me — I always planned to re-home it.

At the end of the Bespoked show I talked with the good people at the cafe & bike shop called Look Mum No Hands! and we agreed I’d leave the bike with them. I have to admit, I’d spent so much time building this bike, staring at its minutia in such great detail that I didn’t want to see it anymore. I needed separation, and leaving it there in London seemed like the perfect thing. It was nominally for sale, but I didn’t pursue it. The Look Mum people put the bike on display in their cafe window and we agreed I’d come get it at some point.

“At some point” became almost three years later, when a friend of mine (Adam of Gevenalle — have I told you, some of my favorite drop bar shifters) was headed to London and said he’d grab the bike, and bring it back to Portland. He did, for which I was exceedingly grateful. If he hadn’t done this it might still be there.

The bike returned broken apart and packed in its travel case. I wasn’t ready to reassemble it — I had no shows to attend, and didn’t need an immaculate bike getting bumped into and potentially knocked over, so it stayed packed in its case and again it went into the far back room of my workshop to for storage.

Fast-forward another few years, to this year, 2021, in May or June. My friend Brian was rummaging in the back room of my workshop, saw the travel case and said, “When are you going to build that stainless bike back up?”

I’d kind of forgotten about it, a case of “out of sight, out of mind.” But the seed was planted. I moved the case out of the far back room to the near back room, and over the next few weeks Brian helped me pull its pieces out of the travel case, assess what we had and what needed to be done. The lights needed to be updated, and this meant re-wiring the bike, putting in the necessary plugs, and then sticking all the parts back together. It had been a long time, and was kind of a head-scratcher, but we got it.

Now, the bike is again ready to go out into the world. This time for real. It’s such a rare and unique machine, I want it to go to the right home. I don’t know what the perfect home is, exactly, but maybe you can tell me.

The last thing I want to discuss is the amount of time I put into this stainless bike’s construction, the hours and weeks, the materials and the components. Each complex bicycle build has its own learning curve — I have to learn how to manage the difficulty it presents — and this bike, still, to my mind, was the most challenging, and in many ways rewarding, of any bike I’ve made. The number of hours I put into it is almost obscene, and gives me pause when thinking about my overall mental health — I don’t know if obsessing over a single project the way I did over this one is a sign of stability and unwavering perseverance, or points towards something darker.

One thing I can say about it is — I will never build another bicycle like this one. I can’t. I’m a different person now than I was then, and this challenge has already been met. It doesn’t mean I won’t make something else that’s equally complex and challenging, but if & when I do I can absolutely promise you that it will be nothing like this one.

What you get when you buy this bicycle is the frame, fork, racks and stem, as well as all the components listed below. The bike comes with a hard travel case, and padding, and — I think this is important — you also get me, the builder. If it’s reasonable, I will personally deliver this bicycle to you; depending on where you live, I’ll bring the bike in its travel case, and will, with white gloves on, reassemble it in your presence so that we can go over all the details of the process. If bringing it to you in person isn’t realistic, you’ll have my presence through Zoom or the telephone, or whatever is best to make sure you fully “get” what this bike needs. As I’ve said, it’s complicated, and I don’t want you, the buyer, to have to figure it out on your own. I want to be there to make sure you understand how it comes apart, and how it goes back together, whatever support you need to make this bike your own. As much or as little as you require.

And to be clear — when I say I’ll be assembling the bike with white gloves, this doesn’t mean the bike is for display only. It’s a bike, and it’s meant to be ridden. As I’ve said, the most important thing to me about any bike I build is that it rides well, and this one does not disappoint. It’s going to be a great machine for the right person.

Cost:

$24,998

Materials:

All the tubes on the frame are KVA stainless steel. The stem and racks are made from chromoly steel that’s been polished & chromed.

Sizing:

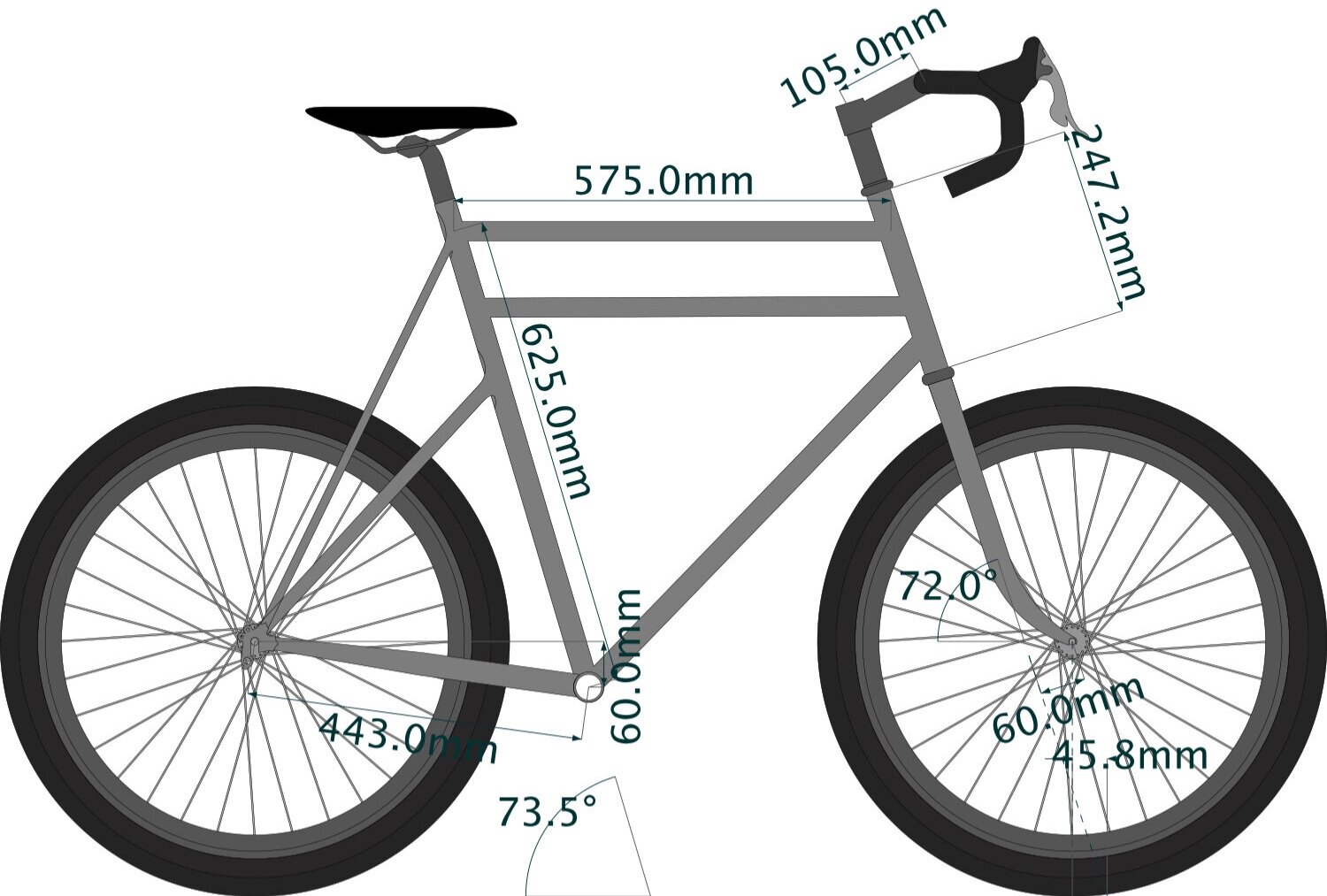

This bike is best suited to someone between about 5’11” & 6’3” depending on arm and leg lengths.

Top tube length: 575 mm

Seat tube length: 625 mm

Stand over height: ~870 mm

Stem specs: 105 mm long, 10 degree rise

Min. & Max. Seat height: ~805 mm - 850 mm (This is measured from the center of the bottom bracket to the top of the saddle. There is a slot in the seat post that currently limits the seat height to these specs. If needed, the slot can be lengthened to adjust the seat height up or down by approximately 30 mm — please ask me about this).

Reach from center of stem to saddle tip: ~523 mm

List of parts:

Schmidt SL connectorless generator front hub

Chris King R45 rear hub, Centerlock disc, 135 mm spacing

Velocity Atlas rims, 26”

Schwalbe Marathon Supreme Tires, 26” x 2.0”

G. Berthoud stainless steel fenders, 60 mm wide

TA Carmina Square Taper Cranks, 175 mm long

TA Triple chain rings, 48-34-24T

Phil Wood square taper bottom bracket

Shimano M900 New/Old stock front & rear MTB derailleurs

Shimano 9 speed HG chain

Gevenalle “Retroshift” shift adapters with Shimano Bar-Con Shifters on Tektro short pull road brake levers

Avid BB7 Road SL Mechanical disc brakes, gunmetal gray with titanium hardware

Chris King Stainless Steel Headset, 1” threaded, polished

Custom Ahearne Quill Stem, 105 mm long, 10 degree rise, polished & chrome plated

Nitto Noodle Handlebar 44 cm wide

Schmidt Edelux II front light

Schmidt SON tail light, fender mount

Brooks Leather Bar wrap (the old style wrap, before they changed it — the good stuff)

Brooks Swift Saddle w/titanium rails

Paul Components “Tall n’ Handsome” seat post, polished

Frame bag custom made by Black Star Bags; fixed to the frame

Kryptonite Mini U-lock with leather shackle cover & 3 keys (fits securely in the lock holder on the rear rack)

The bike comes with a new, hard travel case that measures 26” x 26” x 12”. It’s an edge-pull case with 2 wheels at one end. I’ve packed the entire bike including racks, fenders, and the rest, minus one wheel, into a soft case that was 10” deep. I have not packed the bike into the 12” deep case, and hope that with some care and patience that everything including the wheel will fit. This is a good project for someone who likes puzzles.

There is no other bicycle like it.

One final thing. I’ll tell you a little secret, something I’ve only told very few people. There is a bit of blood inside of this bike. My blood. The actual red stuff that comes out when skin gets cut. In the process of building a bicycle I work with a lot of sharp edges — tools, saws, fresh cut steel with burrs and so on. I try to be careful but it happens sometimes.

I’m not especially religious, superstitious, or magical-thinking, but I definitely believe there are forces working in the universe that we don’t understand and are not always consciously aware of. Just because I don’t understand these forces doesn’t mean their power isn’t real.

My heart and soul go into each bicycle I build. My tag line: “Hand built with love and fury” aren’t empty words. I won’t try and convince you it means anything, but I like to believe that there is power in the symbolism of giving my blood to my work.

I’ve been building bicycle frames for long enough that it is in my DNA. In this other sense, my DNA is in the bicycles I build.

Please contact me if you have questions about this bicycle, or if you want to discuss anything about it.