People keep asking me what’s up with the Pinion gearbox, and what do I think.

Pinion 18 Speed Gearbox

People keep asking me what’s up with the Pinion gearbox.

What do I think?

Everyone who’s seen it is interested, and it’s pretty obvious why. It directly responds to some of the drawbacks of traditional bicycle drive trains. The main issue with traditional bikes is, external drive trains are fragile.

That’s the biggest thing.

Gearbox and Gates Carbon Drive

Derailleurs stick out the side of the bike, they get bumped, knocked, or in the case of mountain bikes, something worse, and that’s it. They’re out of alignment and no longer working optimally, or not at all. And then?

That's it, your ride is over.

So let’s say you’re one of those people who have a Subaru chasing you everywhere you go, your other bike carried on top. You're one of the lucky ones because you still get to ride.

The rest of us, though, we’d have to call mom or catch the bus or god forbid walk.

Shitting the bed

And what happens when we’re out on tour in some remote village, or near no village at all, and your rear derailleur shits the bed?

You get the picture.

So what do I think? I’ve built a couple of Pinion bikes now and have ridden one for a month or so, and I’m still forming my opinion, but there are a couple of things I can say.

First, I’m still intrigued.

I haven’t taken the bike on tour yet, and the most I’ve ridden it on any one ride is no more than about 20 miles. I had some issues with the light wiring and generator — nothing to do with the gearbox — which I think I’ve got worked out now. I’ve been dialing in the little things, getting the fit just so, etc. The season for touring is coming, and that’s going to be the real test.

As I write this there are over a hundred riders doing the Baja Divide route, 1700 miles of off road riding on the Baja Penninsula, which makes me oh so envious. But I couldn’t make it down there for this one.

Anyway, here's my take so far on the Pinion bike:

What I like most is how quiet the bike is. And I mean quiet! The combination of belt drive and internal gearing is almost totally silent. The rear hub is the White Industries XMR thru-axle, and while coasting I can barely hear anything. Over rough roads or tearing through gravel nothing rattles or clanks. I love that. And having the weight of the gearbox centered below me means I don’t really feel it at all. Or notice it.

"Plus" Tires for Off Road Touring

There are only two functional drawbacks I could mention at this point, neither of which are all that big a deal.

One is, there’s a gap in the pedaling. There is a freewheel in the gearbox, and the hub freewheels, so that the two together can cause a gap between coasting and pedaling. It’s not big, but it's more than I'm used to and I have noticed it a couple of times.

It makes me think one of the newer clutch-drive hubs might be a good option for a Pinion bike because the engagement is almost instantaneous. These hubs are silent and smooth because they have no pawls, but they’re a little heavier and kind of expensive. The other thing might be a fixed rear cog, but then you lose the option of thru-axle and the wider rear spacing.

The other criticism I have is the twist shifter. I’m just not a huge fan of them. They were cool when they first came out, and I had one on a mountain bike for years in the 90’s, but after going back to trigger shifters, Paul “Thumbies,” and on drop bars the Retroshift by Grevenalle, I’ve never looked back.

For drop bars Co Motion Cycles makes a really nice twist shifter for the Pinion, based on the same design they use for the Rohloff. It’s big, easy to use, very smooth, and fits up near the stem clamp on an oversized (31.8 mm) handlebar. It looks and feels like something precision-made for a high-end camera. As far as I know, if you want to use a drop bar, you don’t have many options besides the Co Motion shifter. There's a company making a handlebar that splits in the middle so you can fit the smaller diameter twist shifter up top, but that sounds like a lot of engineering to adapt a handlebar to a shifter that just ought to be redesigned.

Pinion Twist Shifter

The compatible twist shifter sold by Pinion only fits a mountain bar. And their shifter doesn’t come close to the quality that the gearbox itself has, which seems odd to me. Why make such a beautiful, functional gear system and sell it with a cheap looking plastic shifter? Maybe I’m just nit-picking here. The shifter works just fine, it does exactly what it’s supposed to, which is turn and run through the gears. But to me it just doesn’t seem to match the ingenuity of the gearbox. I think they’re waiting for, or maybe even depending on aftermarket designers to come up with a better shifter.

Which is exactly what Co Motion did.

Anyway, so there’s a twist shifter. And I’m keeping an open mind about it, and I’m getting used to it. I understand that the gear range on the Pinion 18 speed is so large, and consequently the amount of cable that has to be moved is a lot, like about 12 inches in each direction. I can’t envision another mechanical option that would be much better.

What I’d really like to see is an electric shifter with a little servo motor that does the job. But, if someone out there is working on an electric shifter for the Pinion, please make it so we can patch the battery into dynamo hubs to keep a trickle charge on it. We make power while I ride, so why not use it to keep an electric shifter running indefinitely.

Custom Made Bicycles Rule

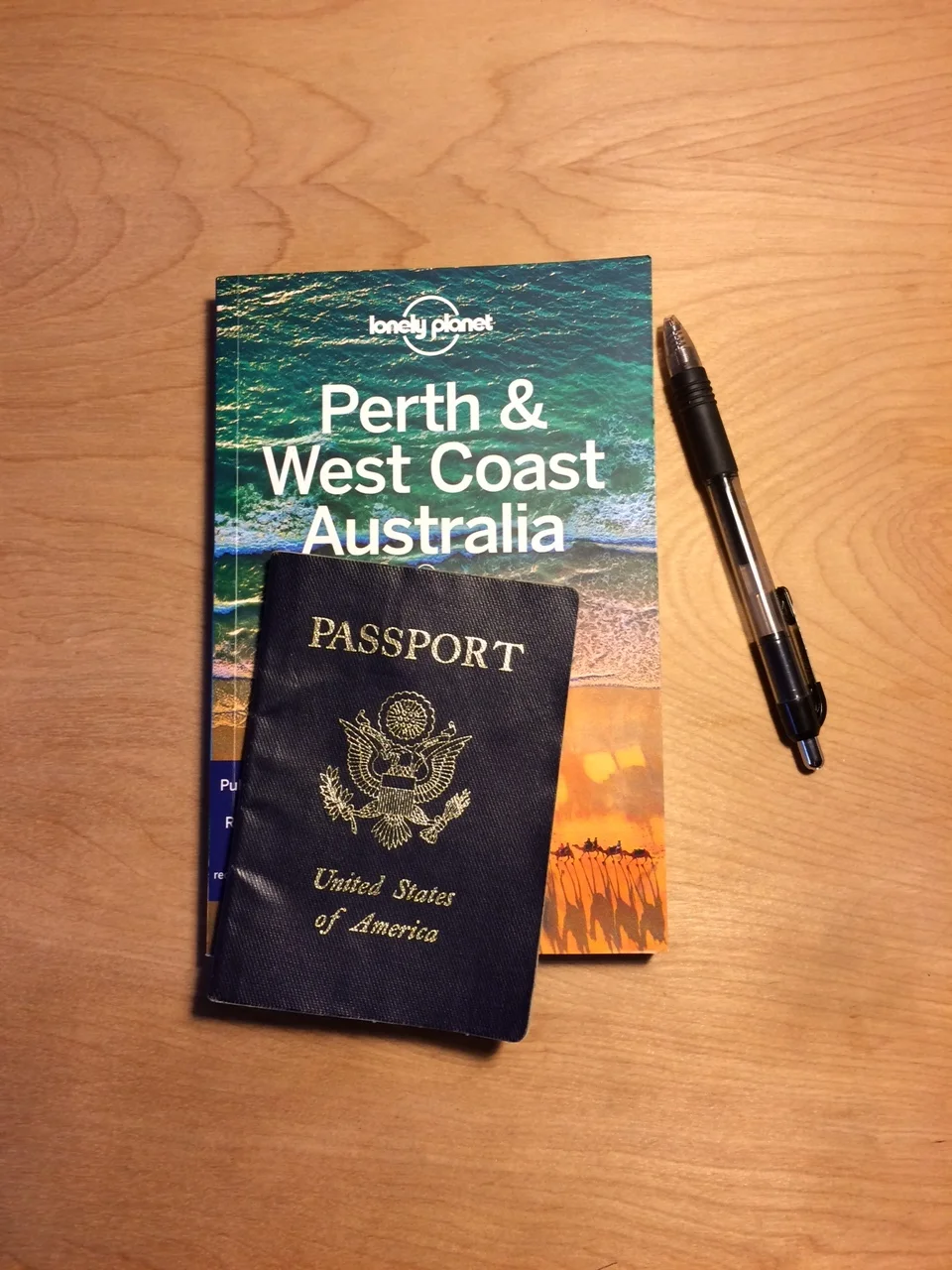

The only other potential down-side to the Pinion system that I can comment on here has nothing to do with function. It’s the expense of it. That, if anything, is what will deter people. I don’t think anyone would disagree that the system presents an exceptional alternative to traditional external drive-trains. But the 18 speed gearbox, shifter and crank set costs right around $2000, and that doesn’t include the bike that you have to have built specifically to hold it.

There are a couple of bike companies in Europe offering stock bikes that include the Pinion system, and they are beginning very slowly to make it into the US. But the cost of these imported bikes is not all that far off what you’ll pay for a custom built bike, so the question becomes, why wouldn’t you go the full mile? If you look at these imported bikes, they appear to be very pragmatic. But at this price point, aren’t we allowed to talk about aesthetics?

Stainless Steel Logo

I guess, I’m writing this, so I can talk about whatever I want to. I don’t like to talk shit on anyone, but really, these bikes just ain’t that cool. Great, they hold the Pinion system. I’m sure they ride fine and carry weight and are stable and handle just like they ought to. But to my mind one of the joys of bicycle design is where function and aesthetics meet, and in my (probably less than) humble opinion these bikes just haven’t quite arrived. This could very well be a cultural difference of opinion. In any case, that's all it is, is my opinion. I like my bikes to have that certain sense of elegance and "coolness" that I aspire to with each build.

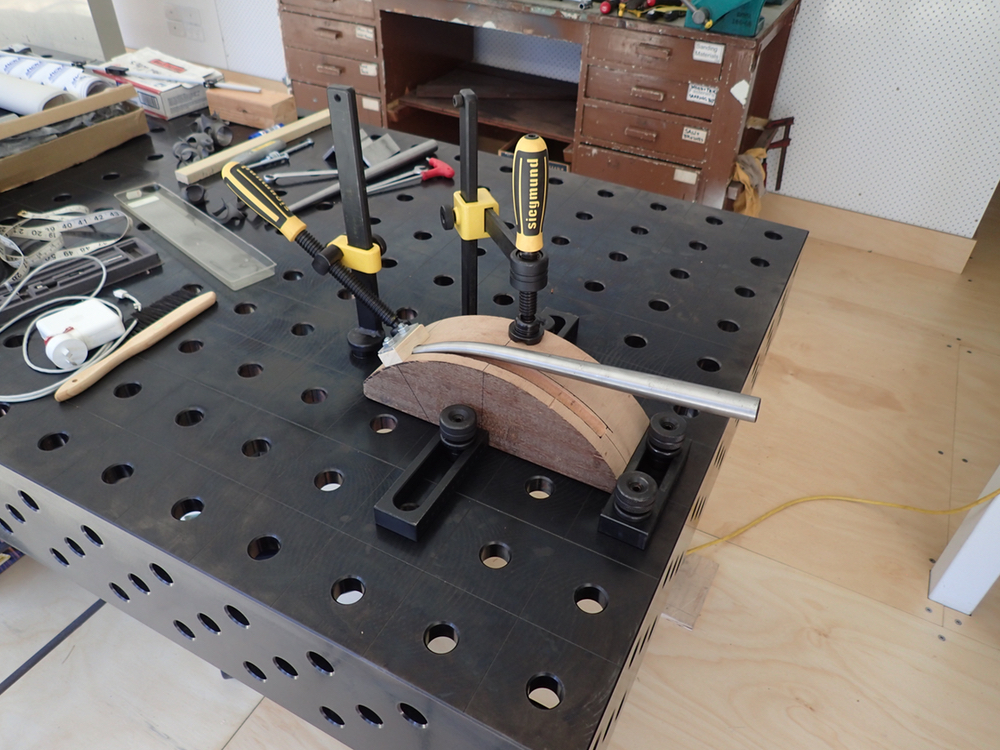

Gearbox Mounting Plate

The last thing I’m going to say at this point about the Pinion system is that I believe it is potentially the best new development in the world of touring bikes. Expensive, maybe, but call it an investment. It has almost no required maintenance and is mostly impervious to any sort of damage during normal use. The only question at this point is its longevity. It feels solid, and I don’t doubt it’s going to last for a lot of years, for tens if not a hundred or more thousand miles. But this remains to be seen.

Alright, now. Here are some photos of the most recent Pinion bike to come out of my shop. It’s a commuter/ light touring bike for Ray. For a more complete photo run, please go over to the Ahearne Cycles Flickr page.

This bike has got the works, and I think I’m most excited about how the racks came out. Especially the rear rack, it's like an old style car. Someone asked if the rear rack can actually hold weight, and my answer is oh, yes, as much as you want. It is tied into the stays at 4 points, and into the fender at 3 points, and the way the rack and fender work together makes it surprisingly strong.

For those of you interested, I am currently taking orders for Pinion bikes to be built by summer, 2017. That’s for both Ahearne frames, and collaborative bikes made by Igleheart & myself, under the name Page Street Cycles.

Keep an eye out for photos of the next bike on the list, which is a ladies mitxe with the Pinion gearbox. It’s going to be something special.

Thanks for reading, and enjoy.