Writing on Life and Death

Note to readers: This writing is more personal than what I usually post here. I love to write and tell stories, and I’ve tended to post mostly bicycle-centric writing. They are personal in the sense that they’re my stories about bicycles, but there’s an invisible line I’ve drawn that delineates between what I’ve thought is appropriate for a bike-biz website and what’s personal. This is my problem, not yours; I understand that I am my business and my business is me; we are separate, but we’re also the same. Here I’m attempting to bring them closer together. If you’re only interested in reading about bikes you might want to skip this post and wait for the next.

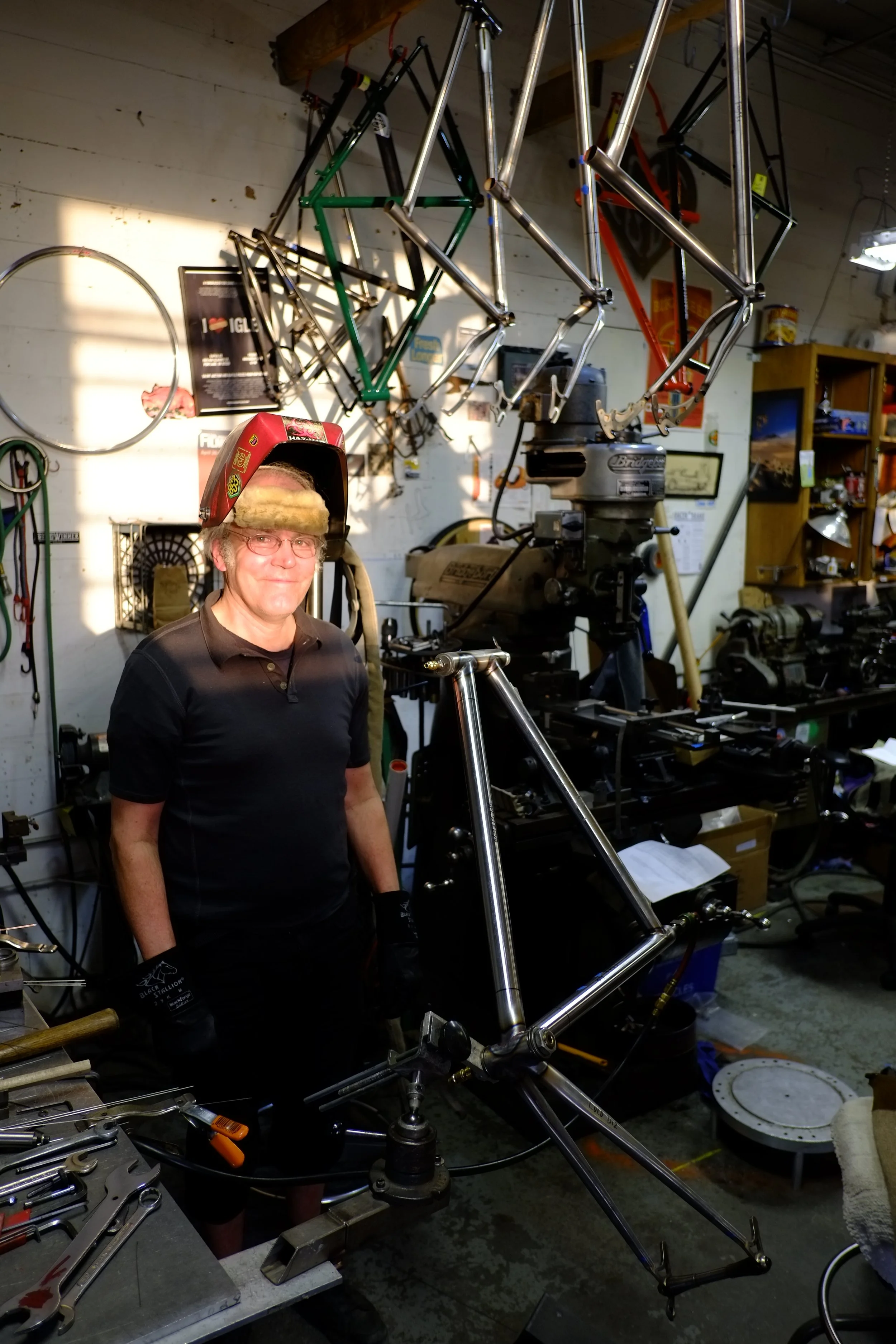

This is an extended excerpt from a piece I recently posted on my Substack platform. Often, but not always, there’s a bicycle somewhere in my story, just like there’s usually something bike related in my life. But, you know, I lived a lot of different kinds of lives before I began making frames and racks and the rest, and some of these stories I think are worth telling. It’s up to you to decide if they’re worth reading.

If, by chance, you do, please head over and sign up on my Substack account and you’ll get the latest writing from me on bikes and life and all the rest.

Thank you for reading. Every shared story is an opportunity for connection, and here we are.

Some Wins

Sometimes when I sit down to write I become paralyzed by the number of possible things to write about. It’s a small existential crisis that can happen when I’m confronted with a blank page. Like, why would I write about one thing and not another? I could write about my new garage or the collapsable rear rack I’ve built for a travel bike. I could talk about the struggles of self-motivation in the winter when it’s cold and dark, or I could tell you about my friends who recently drove down from Seattle and nearly died in a car crash. I could explore the current political nightmare unfolding in this country, although I don’t want to bore you, or myself, nor do I want to make myself throw up.

Ben Franklin said it well

Maybe you can imagine me sitting here in front of my computer at around 5 in the morning with a cup of coffee steaming beside me, hands poised over the keyboard, a brand new document open on the screen, all white space except for the little cursor blinking steadily like a timer telling me how much of my life is passing. I can sometimes sit frozen in this position for ten minutes, twenty minutes, my fingers not moving, my body leaned slightly forward as if into a swirl of ideas, waiting for the first words to materialize. All I need is a single word or phrase to flutter out of the fog and inspire my fingers to type.

When it’s the bleak period in the middle of winter and I feel stuck, lost, unmotivated, rather than getting hung up on what I’m not doing, a helpful practice is to recount wins. Big or small, it doesn’t matter. Just acknowledging that I have done a few things besides lay around mouth breathing, eating bonbons on the sofa or whatever. I’m an active person, I like having projects and problems to solve, questions to answer, things to make, ideas to explore.

Let me recount some wins.

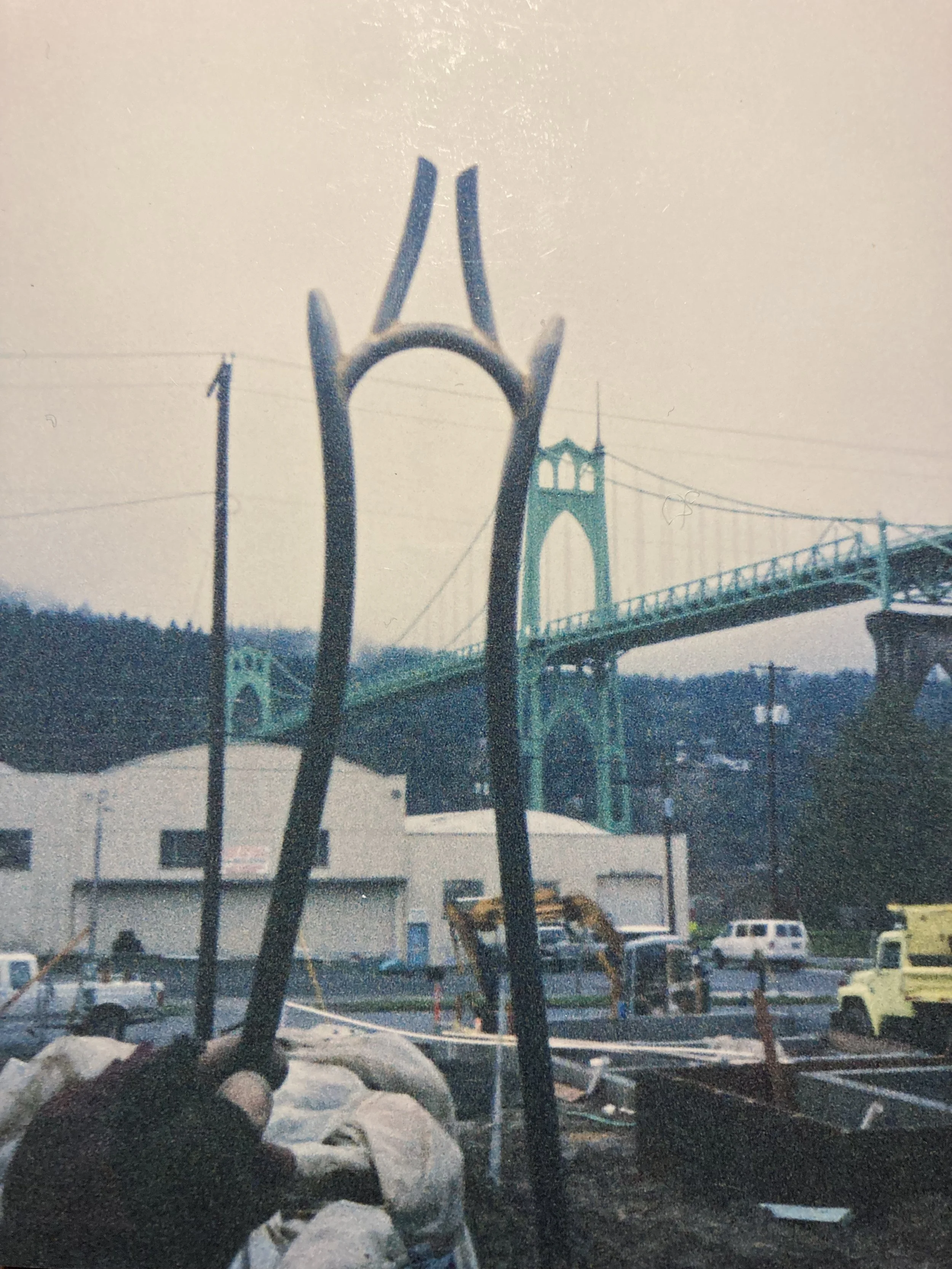

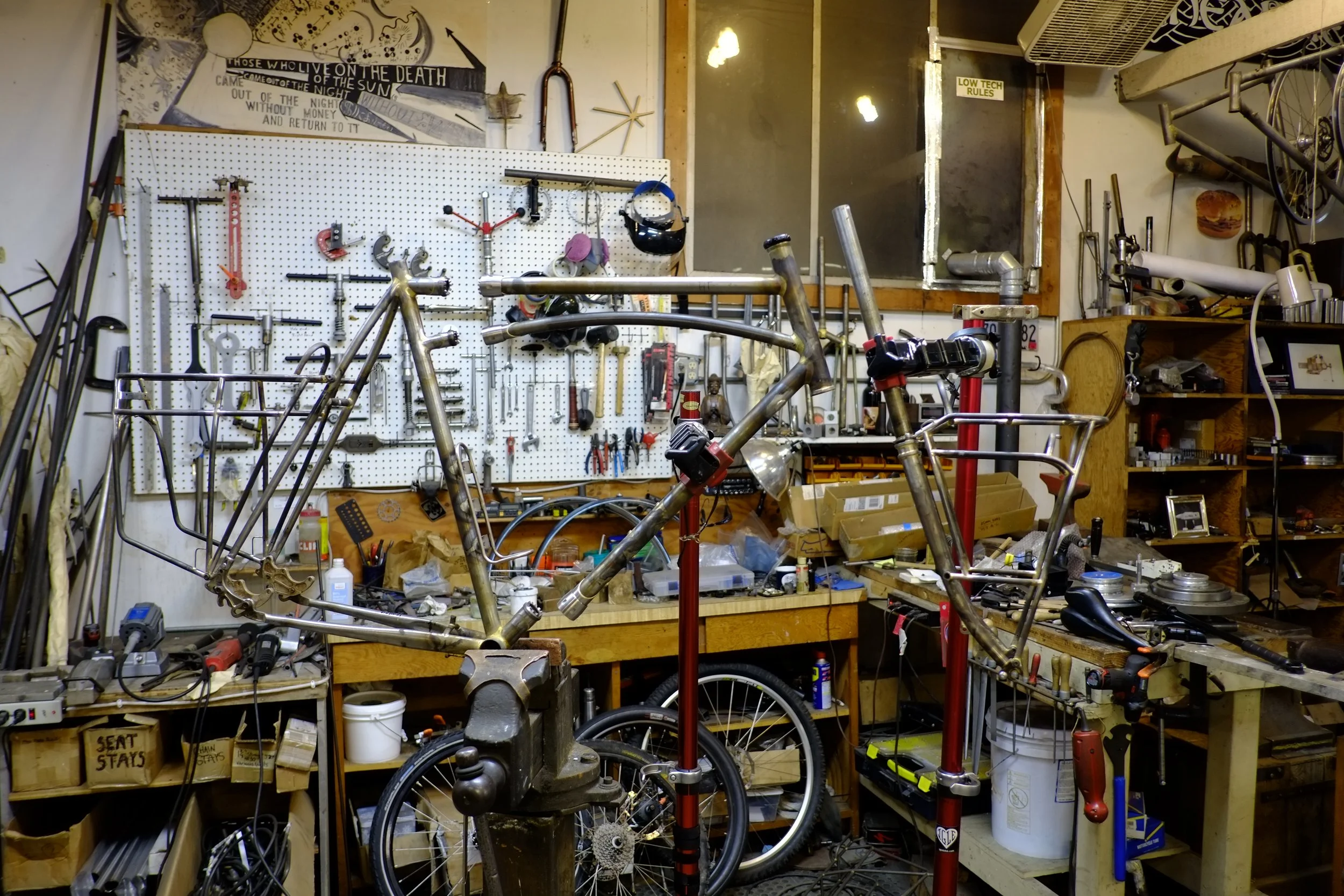

1) It took over a week, but I was able to organize and consolidate my steel tubing. I sorted everything by diameter and shape, marked each tube, gathered like with like and stowed them in boxes. Doing so allowed me to mostly clear out the back bedroom of my house, which has been a catch-all cluster-F since I moved in. I’ve been saving this one closet just for my steel, a dry space to help with rust prevention. I built sturdy shelves in it and can now easily see and access my inventory. Simply knowing what I have is amazing. Organization is definitely a win.

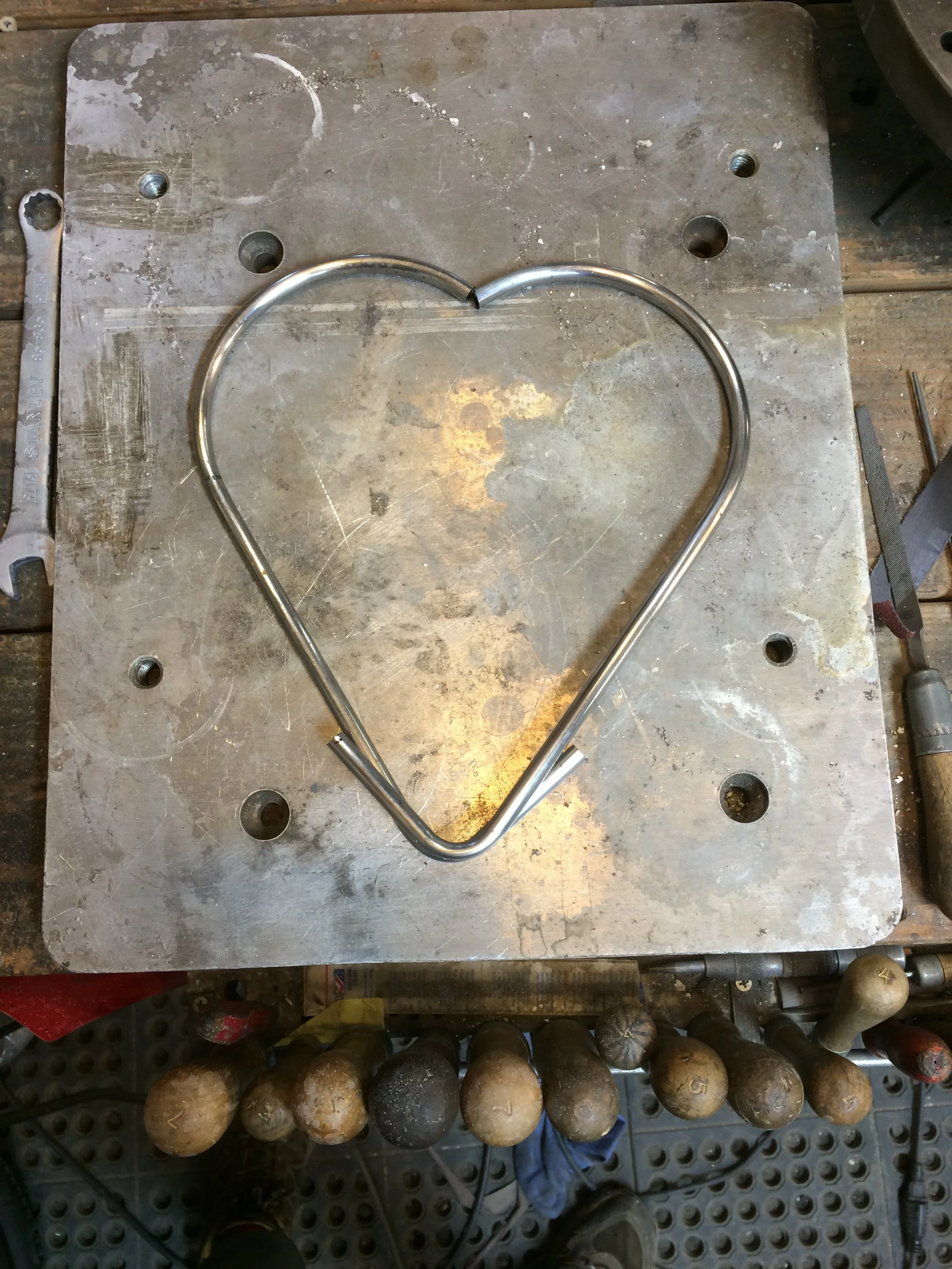

3) A few days ago I finished a rear rack for a travel bike. This is a prototype travel rack, the design has been floating in my ideas for months and I finally made it in steel. The rack breaks apart and packs flat, fits in the suitcase with the rest of the bike. It’ll hold small panniers, and better still — it’s the right size for the frame and the small wheels so it doesn’t look like a badly fitted add-on. And with this rack the travel bike suddenly becomes a viable touring rig. A simple, sensible rack for the win.

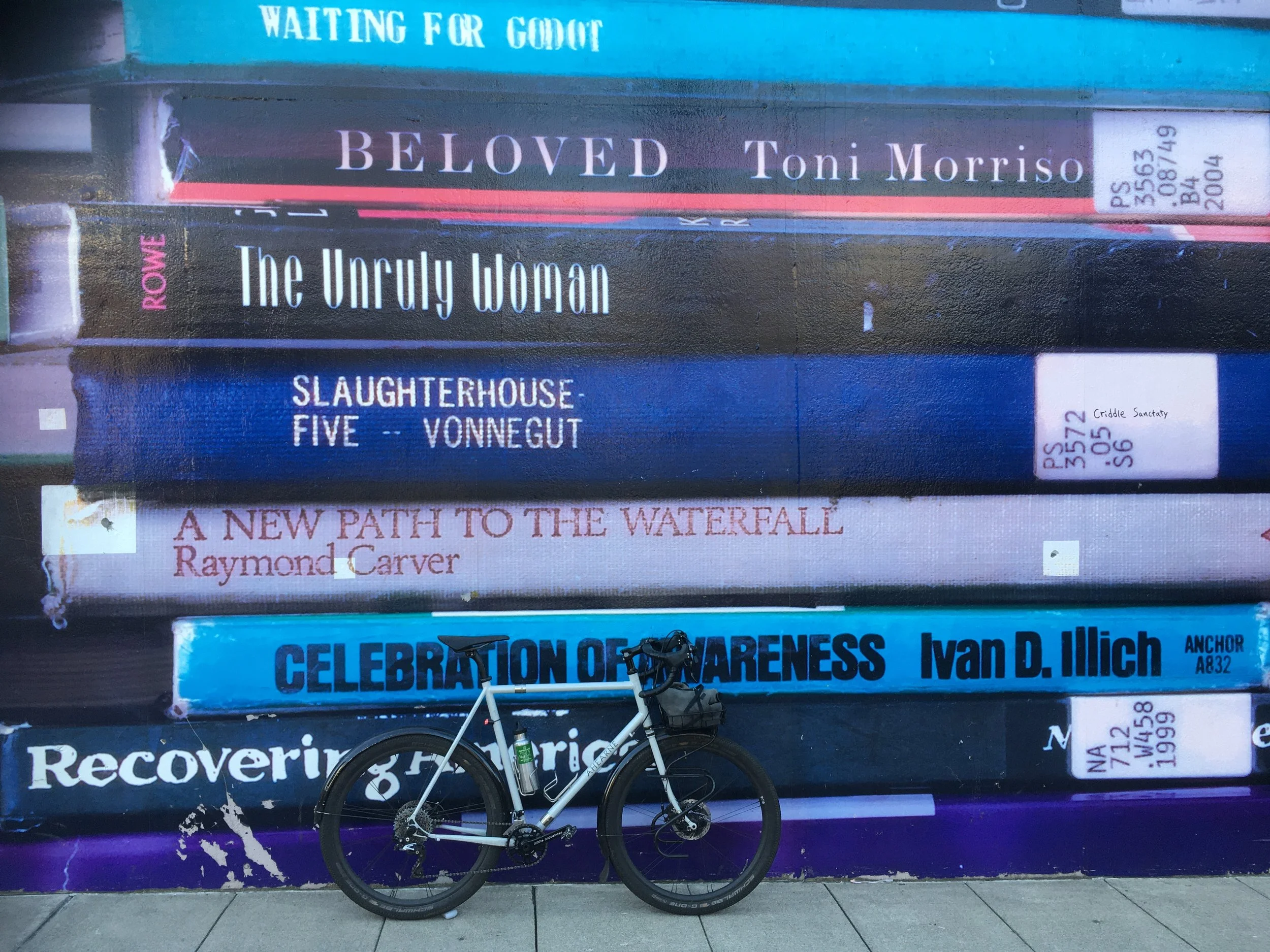

4) Speaking of travel racks, have you seen the newly updated Page Street website? The “Viajero” travel bike is the focus, and I’m taking orders now. There is a load of information on the site, please take a look and let it inspire you.

A newly renovated website, definitely a win.

6) Lastly, for now, the two biggest wins I can think of are my health and my life. I put these together because both have come up recently.

One, I got the flu. I don’t get sick very often. The last time was with Covid just at the beginning of lock down. Hard to believe that was almost 5 years ago. Being sick sucks, especially when I have so many things to do and people waiting for me to make their bikes. I was only laid up a few days, but the mental fall-out from being physically depleted takes longer to get past.

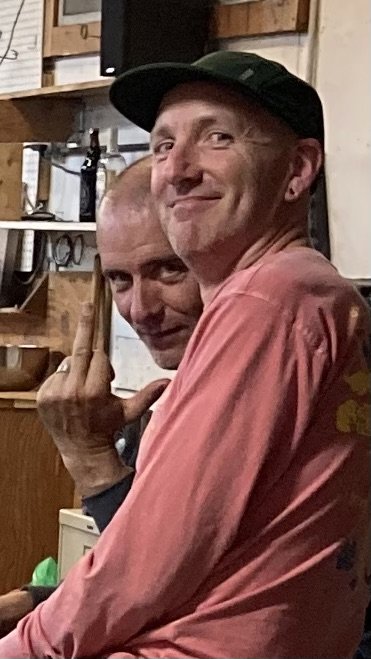

The simple reminder to be grateful for being alive is the last thing I’ll discuss here. Seems obvious, but I think we forget. I know I do. I mentioned earlier that my friends were in a car crash. This was the last Thursday before Xmas, they were driving down from Seattle, ostensibly to bring an old Raleigh road frame to me to see if I could fix a cracked chain stay.

Straight on

A young man working as a pizza delivery driver shot out of a parking lot at just the perfectly wrong moment. My friend Alex, who was driving, later said all he saw was a split-second flash of the kid’s minivan slicing across his vision. No time to brake, full t-bone impact at about 40 mph. It simultaneously set off all 8 airbags in the Subaru. It was like an 8-gun salute punctuating the massive crunch of metal and exploding glass. That’s how fast it can happen. The airbags saved their lives

.

When I arrived to pick them up, Alex and Laura looked houseless beside their pile of stuff. My car’s headlights lit them up and I saw their tears, their faces streaked, puffy and red. The wind slapped at them and they were barely out of the rain. It was the saddest looking couple I think I’ve ever seen. They had scrapes, sore spots, bumps and bruises, but the worst damage was to their sense of safety. Their world had just cracked and now appeared to be dangerous, terrifying.

If you’d like to continue reading, please head over to my Substack account where you’ll find the complete piece. While there, if would like to know when I post again, please sign up to receive email notifications. I swear I won’t spam you, sell your info, nothing nefarious. If in the future you feel like I’m posting too much you can always opt out, and no hard feelings.

Again, thanks for reading. The practice of living is the hardest thing we do, it’s so big, and we get better at it when we’re in it together.